Hello all, …

Here we go for the phase 2 of the homebrewed "DIY-Case tuned housing VIM3 + Modified TONE2 Pro", all-in-one assembly, this part deals with the modification of the DIY-Case and the assembly of the modified Tone2 Pro on the VIM3 Pro.

If you have missed the phase one, you can read all about it here

… Let’s go for the second phase of this assembly !!! …

solid but removable…

Because I always want everything to be easily removable, I first had to think about how the assembly should be mounted.

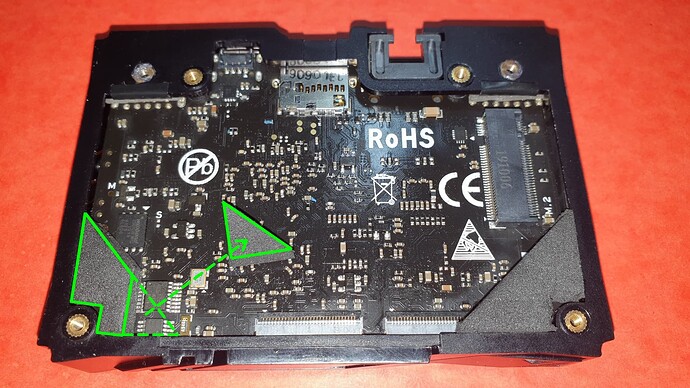

I first thought that the Tone2 Pro should be fixed at 4 points (its 4 lower screws).That was before I noticed that Khadas had used 2 types of screws to hold the lower-rear plastic part of the Tone2 Pro !

2x M2 screws (no problem there) and 2x M1 screws (much harder to find ! )

How to do for the 2x M1 screws ?..

As I needed M1 screws longer than the one in place, I first thought of re-threading M2 screws into M1 5 or 6mm long in their end part, but I found it too long to do , not necessarily the tools to do it and surely too fragile …

So I gave up replacing the M1 screws, I thought that 2x M2 screws plus the 40-pins header would be enough to hold the Tone2 Pro.

What followed gave me reason not to waste too much time with these 2x M1 screws which would remain as originally.

Then how to close the box…

I also had to find a way to close the box…

The metal plate is threaded in M2, so I just had to find a way to hold this metal plate on the DIY-Case without going through the inside as originally planned…

The only solution, making captive nuts in the body of the DIY-Case and in its lower cover…

Lock the nuts in the plastic parts of the DIY-Case…

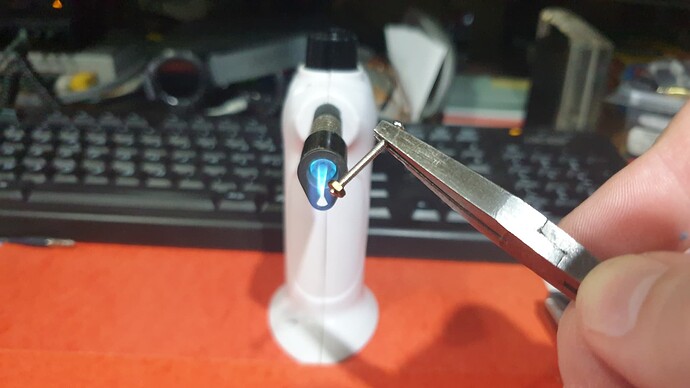

By using a small torch to heat a nut held on an M2x30 screw, it is easy to melt the plastic to trap them.

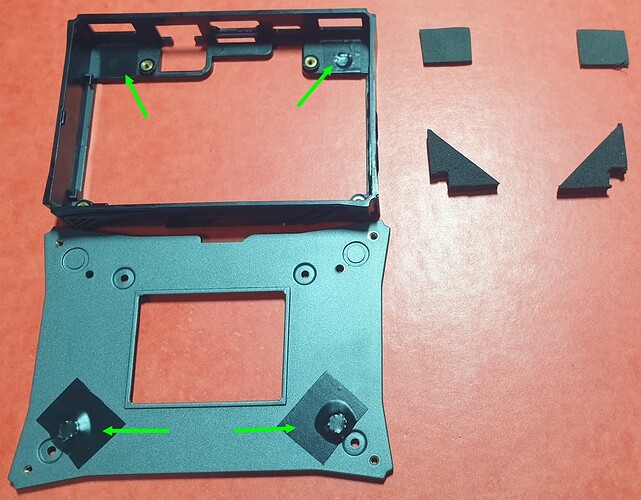

…in the body of the DIY-Case…

…in the lower cover…

All that remains is to trim everything and voila !!!

Let’s go to the assembly !!!..

The assembly :

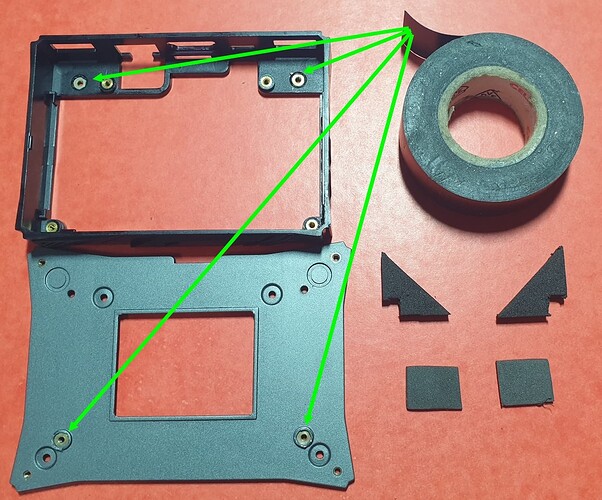

To prevent the captive nuts from making contact with the electronic parts of the VIM3, I isolate them with isolating plastic tape.

And since 2 precautions are better than one, I planned to add additional pieces of insulating foam…

As everything is ready, it’s time to place the VIM3 Pro in the body of the DIY-Case…

Placement of the VIM3 Pro in the body of the DIY-Case…

As the two original M1 screws of the Tone2 Pro remain in place, the two screws of the venti-rad of the VIM3 Pro next to them will also be used and mounted as originally…

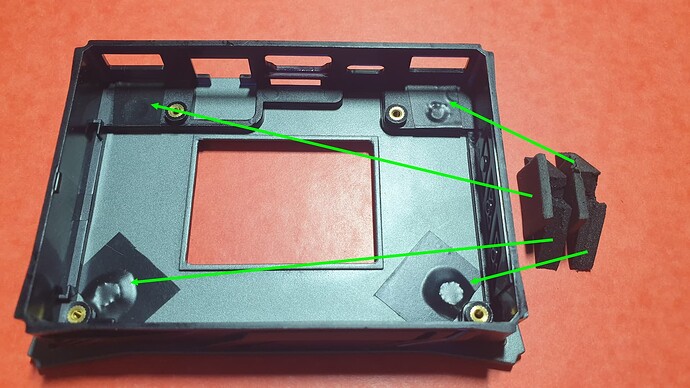

After trying to place the Tone2 Pro on the DIY-Case, I found that the corners of the lower part of the DIY-Case were too protruding,…

…so I decided to reduce them…

…limiting the number of screwing constraints…

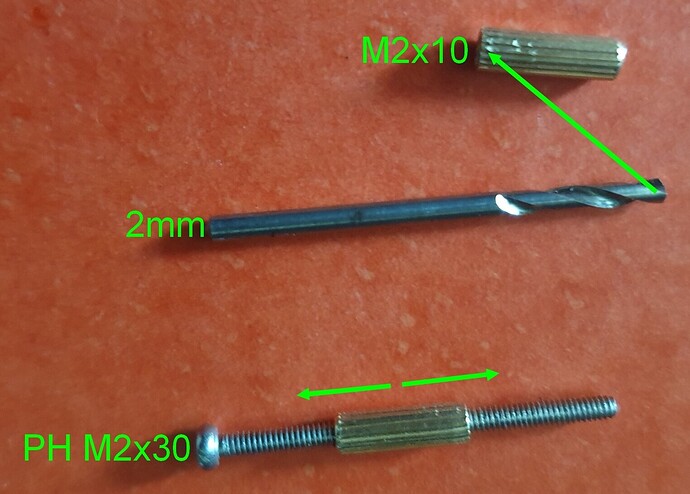

To fix the Tone2 Pro to the assembly, you must limit the number of screwing constraints. We therefore need to drill the 10mm spacers with a 2mm drill so that the screw can slide there…

…the spacers and their washers are ready…

All that remains is to adjust the PH M2x30 screws to the correct length…

Installation of the lower part of the DIY-Case…

By setting up the isolating foams we can see that the one in the lower left corner covers two integrated circuits. To prevent them from heating up, we cut the foam…

We can now screw the lower part of the DIY-Case on its central part with 2 of the the original screws and prepositioning the 2 main retaining screws PH M2x30 cut to 23.7mm…

Finalizing the tightening of the venti-rad…

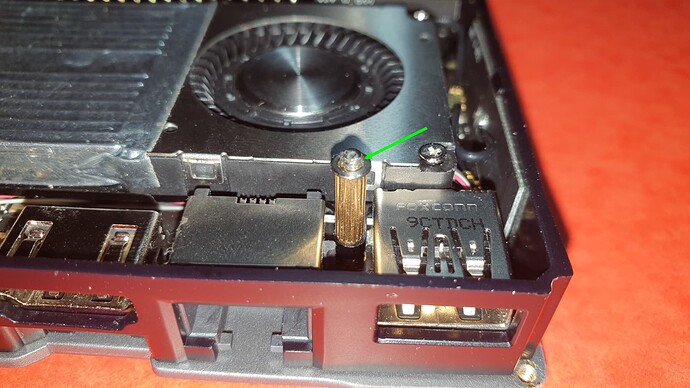

By pressing strongly on the venti-rad screw the 2 PH M2x23.7,…

…so that we can thread the spacers and the washer and that the screw protrudes by about 1mm…

Setting up the Tone2 Pro on the VIM3…

Now we can present the 40-pins header of the Tone2 Pro on the one of the VIM3, taking care that the washers placed on the PH M2x23.7 screws do not fall out…and tighten the two main screws PH M2x23.7…

The assembly is now finished,…

We can see the 2 to 2.5mm of free ventilation space thanks to the use of the 40-pin 11mm header instead of the 8.5mm one…

we can go to the finalization and the closing of the box…

Closing of the box with the metal plate…

The metal plate can be used as a heat sink, we are not going to deprive ourselves of it…

We cut a rectangle the size of the open part of the lower part of the DIY-Case in a plate of thermally conductive paste 5mm thick and we slide it into the gap…

…fixing the metal plate…

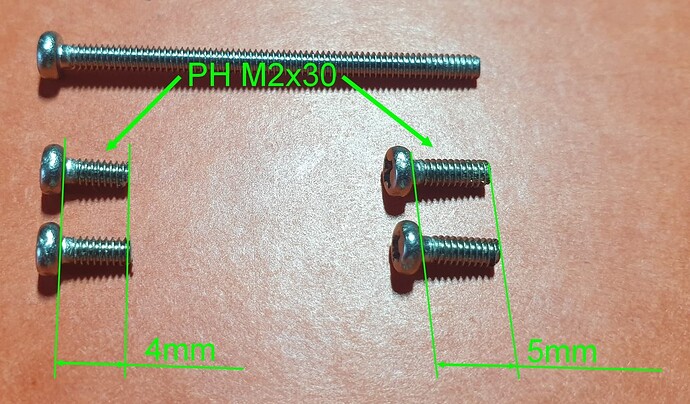

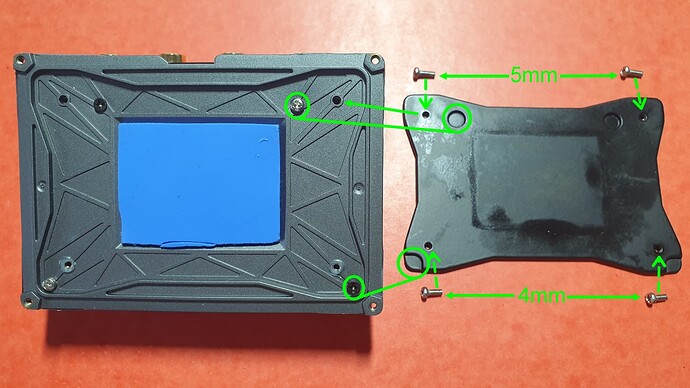

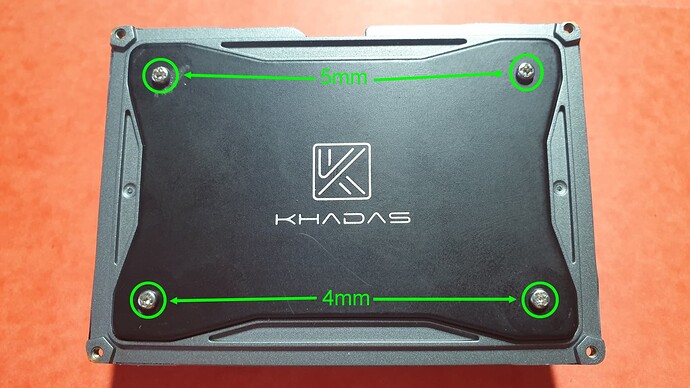

To fix the metal plate we need 4 M2 screws of two different sizes…

2 M2x4 and 2 M2x5 screws that we cut from 4 PH M2x30 screws…

The screws go in this arrangement…

Finalization…

The assembly is now complete…

All that remains is to have the pads on the screws…

…so that they do not scratch and allow the metal plate to dissipate the heat…

List of what we needed :

BOARDS and CASE :

- Khadas VIM3 Pro (or not)

- Khadas Tone2 Pro

- Khadas red DIY-Case (and its metal plate)

ELECTRONICS PARTS :

- 40-pins 11mm header (ordered 8 pcs = $6,04)

BRASS STANDOFF :

- 2x M2x10 (ordered 6 pcs = $0,28)

SCREWS :

- 6x M2x30 PH (ordered 50pcs = $2,11)

- 2x M1x4 (Khadas Tone2 Pro parts)

- 2x M2x8 (Khadas VIM3 venti-rad parts)

- 2x M2x4 (DIY-Case parts)

WASHERS :

- 2x M2 or M3 (recycling)

COSTS :

without boards and case = $8.43

I therefore give you an appointment for the following phase :

- DIY-Case tuned housing VIM3 + Modified TONE2 Pro (PHASE 3)

The tests and operational problems of the finished assembly.

See you soon !

DerFu