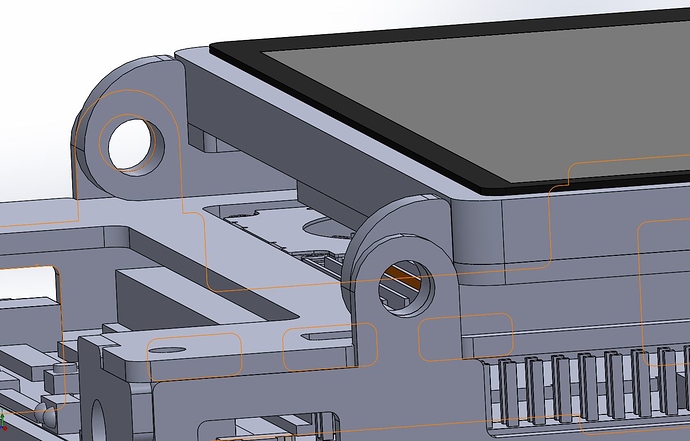

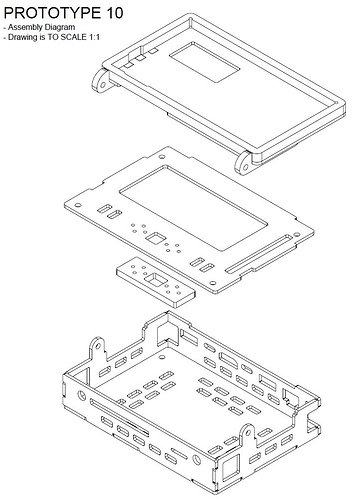

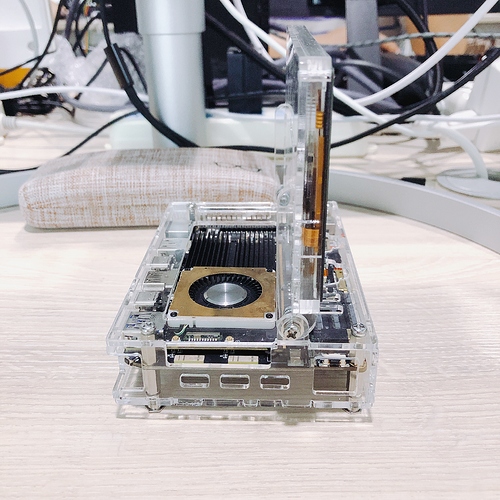

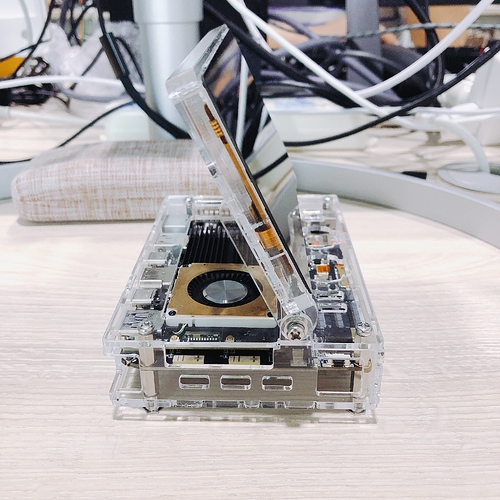

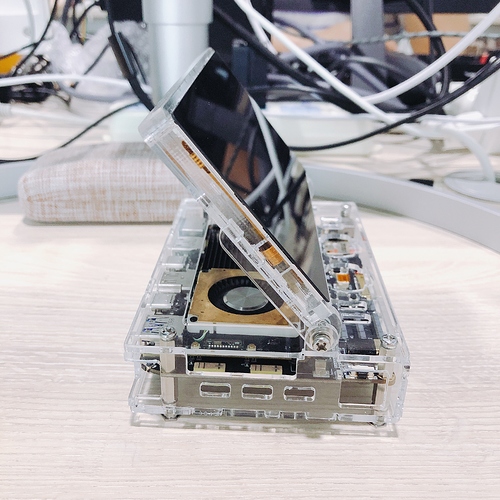

Alright, I think the next version can have a bigger screen.

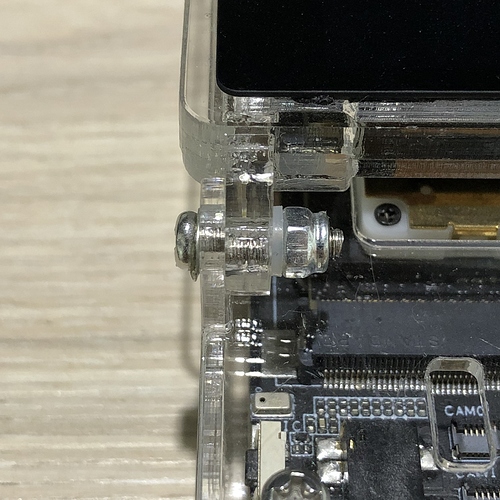

Been looking at some blindnuts, the external diameter alone is 5.38mm - a tad too large for that acrylic part.

The spring / washer isn’t so much of an issue though - will attempt those first. Likely the spring will add sufficient tension to the nut, so it doesn’t come loose as easily.

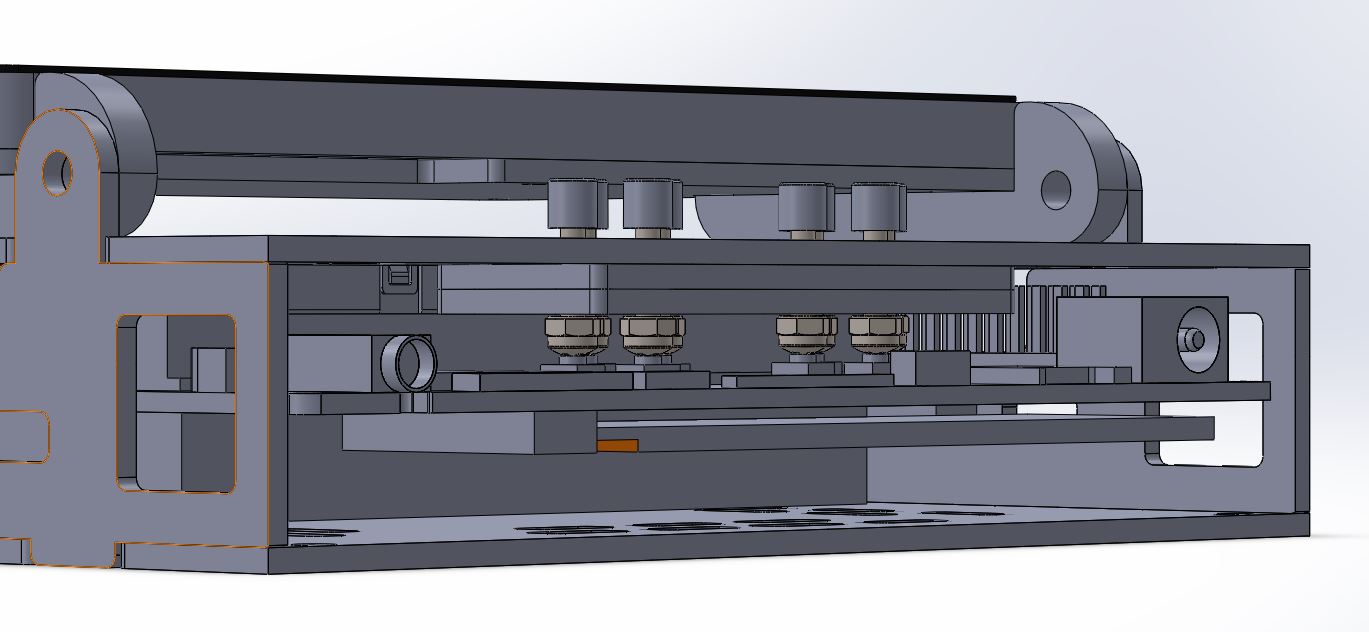

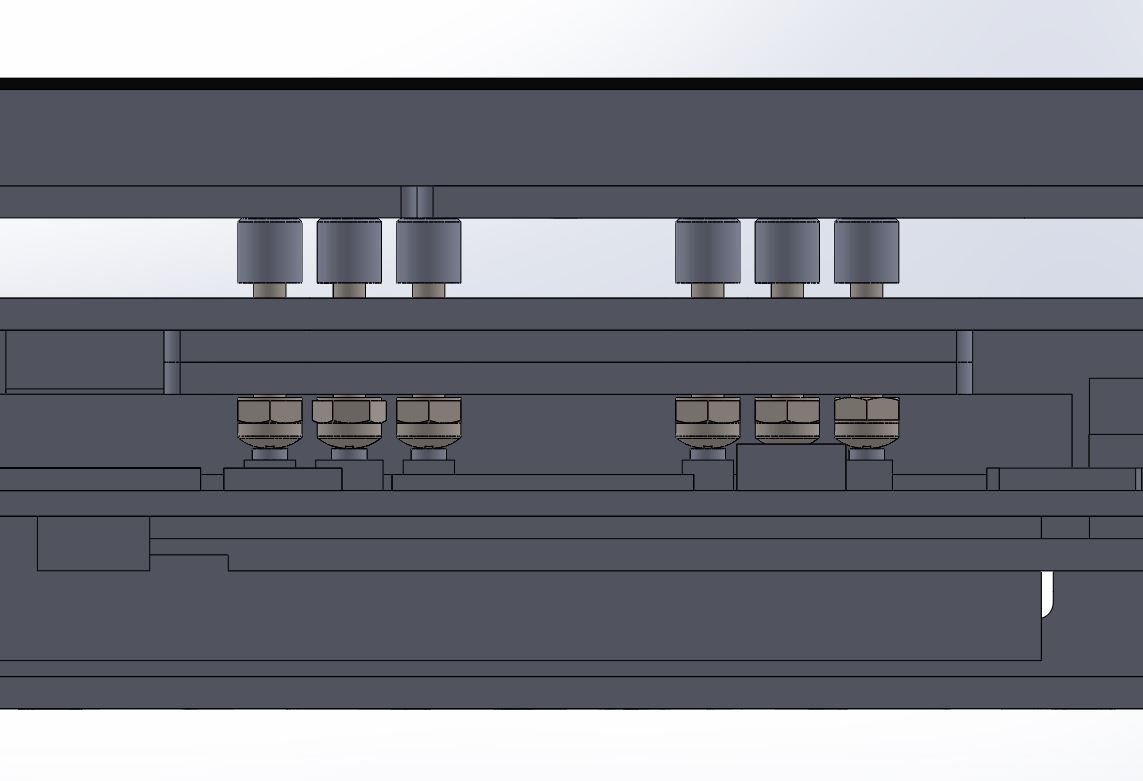

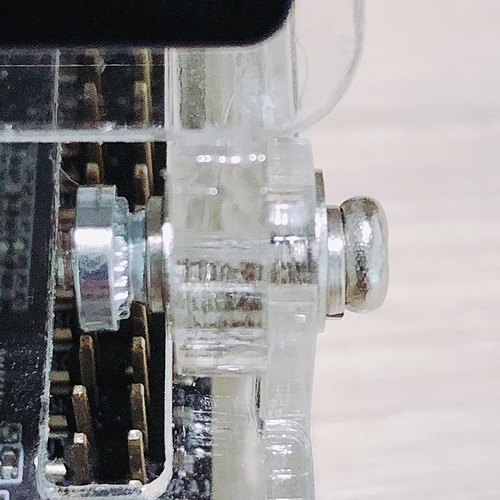

Finally figured out how to design external buttons that are simple to manufacture, assemble, and work properly. No need for the use of springs or other complicated mechanisms. Springs could be used to make the mechanism “softer”, but entirely unnecessary.

Those “button caps” are M2 blind nuts.

The Tone Board nuts probably work too, though probably have to add some glue to keep them from slowly coming loose.

Okay this works quite well!

Update: Works like a charm  Thanks @RDFTKV!

Thanks @RDFTKV!

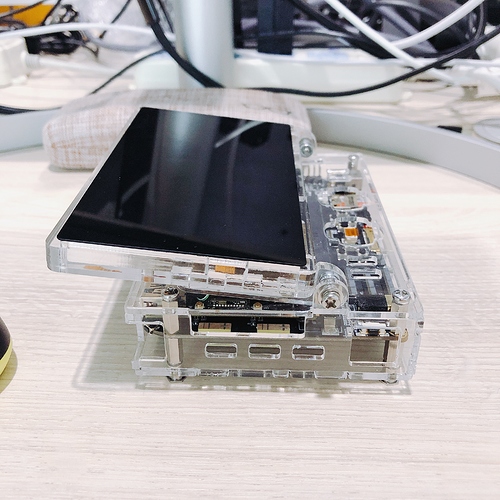

Screw - Spring - Washer - Acrylic - Acrylic - Washer - Spring - Nut

I do believe it will eventually come loose (the nut will probably loosen due to vibration, wear, etc), so some removable locktite is probably necessary for longterm usage. However, from what I found just now, is that at first it starts of stiff, then after some time it finds “an equilibrium”, which is looser, but this does not change afterward. The hinge tension seems stable.

The “equilibrium tension” is sufficient to maintain the screen at any angle.

Thanks, but the credit is yours.

Using lock washers for spring tension is a good idea.

It looks good. I noticed if you scroll the photos up and down, you see an animation of the display going up and down by itself. There’s you ad.

Oh that’s a lock washer, on alibaba they classified it as a spring. I was just thinking about using it as a pre-tensioner.

Ahh this is informative, I understand how it works now. Apparently, there’s some debate as to its effectiveness, also it should not be used together with a conventional washer.

Mmm probably an even better solution would be to use a smooth shaft to isolate the bolted components from the hinge rotation. And add some toothed washers (or maybe even Kep Nuts, if I can find any) to keep the bolts in place. Will need a bigger hinge though…

Update: Okay it works just fine without the conventional washers. So its Screw — Lock Washer — Acrylic — Acrylic — Lock Washer — Nut. You have to screw it even tighter to begin with (probably biting into the acrylic), then wiggle the hinge say a 100 times, and the tension becomes stable.  (It makes noise without the conventional washers though!)

(It makes noise without the conventional washers though!)

Just thinking out loud.

What about…

Screw- external star lock washer- Stationary Acrylic- Rotating Acrylic- nylon washer-metal washer- Nut. A second nut could be used as a Jam nut to further resist spin off.

Thinking on this is, Screw resists motion because the star washer bites in to the stationary acrylic and the screw. The nylon washer against the rotating acrylic will slip with either the acrylic or the metal washer, hopefully reducing the nut from being spun off.

Everything but the metal washer and star washer could be nylon fasteners. Should be quiet.

Update: I see M2 Nyloc Nuts(nylon-insert lock nut) are available. Should completely resist spin off. So Khadas metal M2 screw and M2 Nyloc nut might be better than nylon screw and nut.

Just ordered some star-toothed washers, nylon washers, and nyloc nuts. I’m using M3 for the hinge, as M2 components are a little rarer to come by. Also the narrower M2 shaft allows more hinge-play and less support.

So for the gamepad buttons extending out of the case, I’m hoping the 6mm shaft and shorter M2 screw would reduce the play (and thus slippage) of the “plunger”.

M3 even better, more robust.

Hope it works, or I’ll feel bad about you ordering that stuff.

I think the star toothed washers and nyloc should work fine. Not too sure about the nylon washer though, I used to help my friend build 3d printers that had delrin slip-and-slide components (expensive though)!

Yes, nylon was the cheapest slippery material I could think of, other than a felt washer.

Look forward to seeing the arrangement.

OK. Last one and I’ll stop.

Any chance a shoulder bolt/screw could be had at this size, though it might be cost prohibitive.

Okay just ordered a bunch, the shoulder diameter is 4mm it seems, may have to drill a larger hole into the hinge. M3 shoulder screws aren’t too expensive over here. x12 for 1RMB each - probably overstock (hope they are good, sometimes get crappy things and have to throw away, very wasteful).

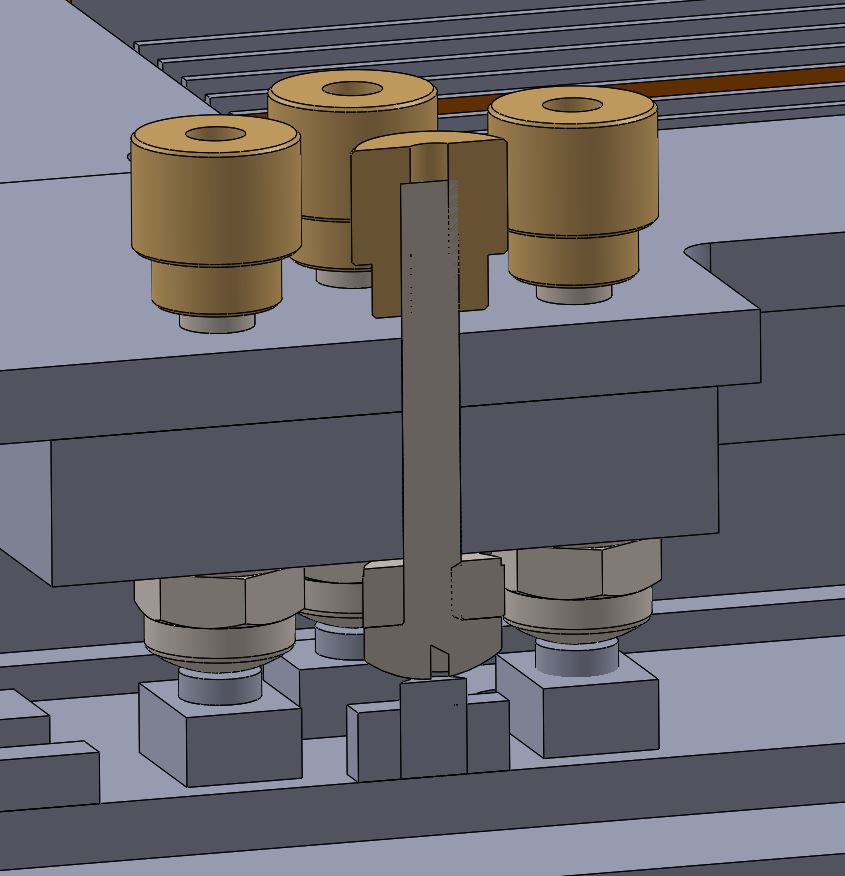

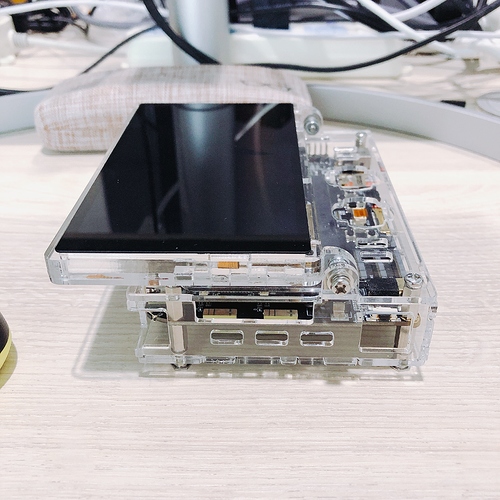

Okay the bare minimum for an “unloosening hinge” is the following:

Screw - Toothed Washer - Stationary Acrylic - Moving Acrylic - Nylon Washer - Nyloc Nut

I’ve already wiggled it a 100 times and it’s fine, literally until my wrist got really tired. Probably won’t come loose for months.

Thanks @RDFTKV

The shoulder screws haven’t arrived, yet. Haha

I’m impressed that a nylon washer, that size, could be so quickly found.

You mentioned a noise before, on one of the combinations. Is this arrangement noisy?

M3 nylon washer, yes tonnes of them here, bags and bags full.

This one is a lot less noisy, be sure to adjust the tension to reduce the noise. The noise comes from the acrylic rubbing together.

I’m waiting on a new prototype with better hinge-tolerance. I used 2 surfaces to control the “mating-distance”, lets see if it works with less noise.

Hinge of Unloosening: