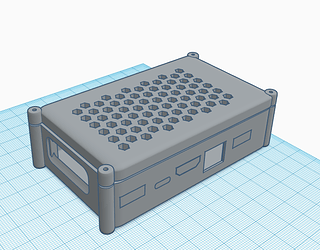

@AlexBudd Here is the modified model as you asked with smaller 5mm holes,

I made the screw holes for M2 and has 2mm around it to hold the the screws without breaking, (this is problem associated with 3D print, which have tendency to crack from the sides if the screws are big, or excess stress is applied)

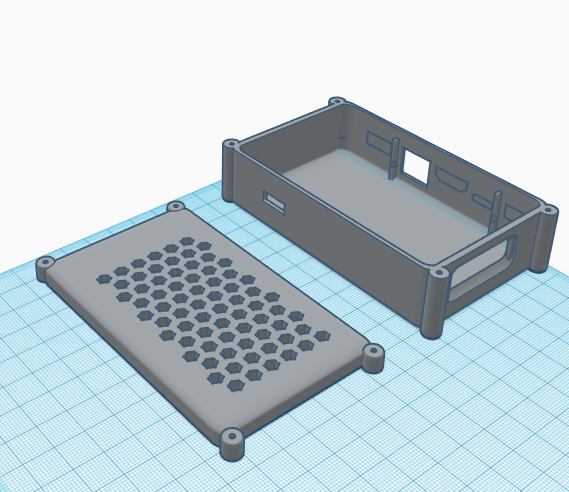

they are split as two parts for easy printing,

Download link here: https://drive.google.com/drive/folders/1sD01FeS2PDbBIFMYymKpP8BBv2Wt7vmg?usp=sharing

Hope you like it, please send me pictures of the print once it’s finished, Thank you

Good Day!

Recommended settings:

use support material for the body, not for the lid, print it in the way it is, large flat side on the bottom

Also try to use ABS filament for rigidity