OK - draft is in.

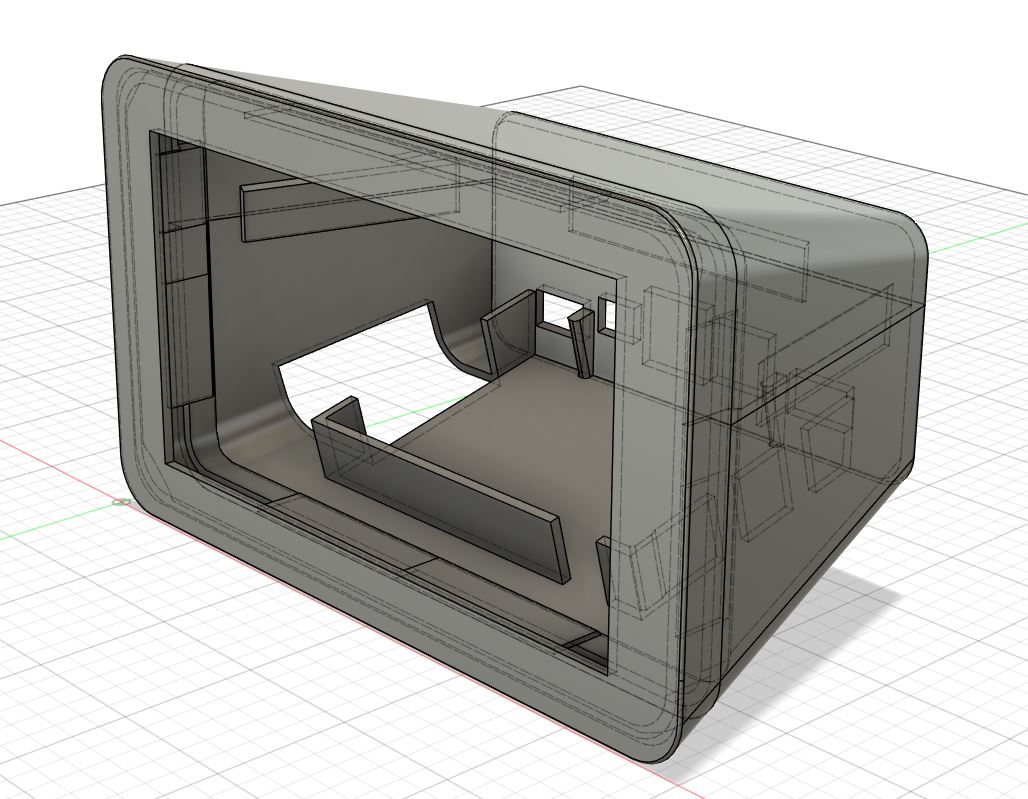

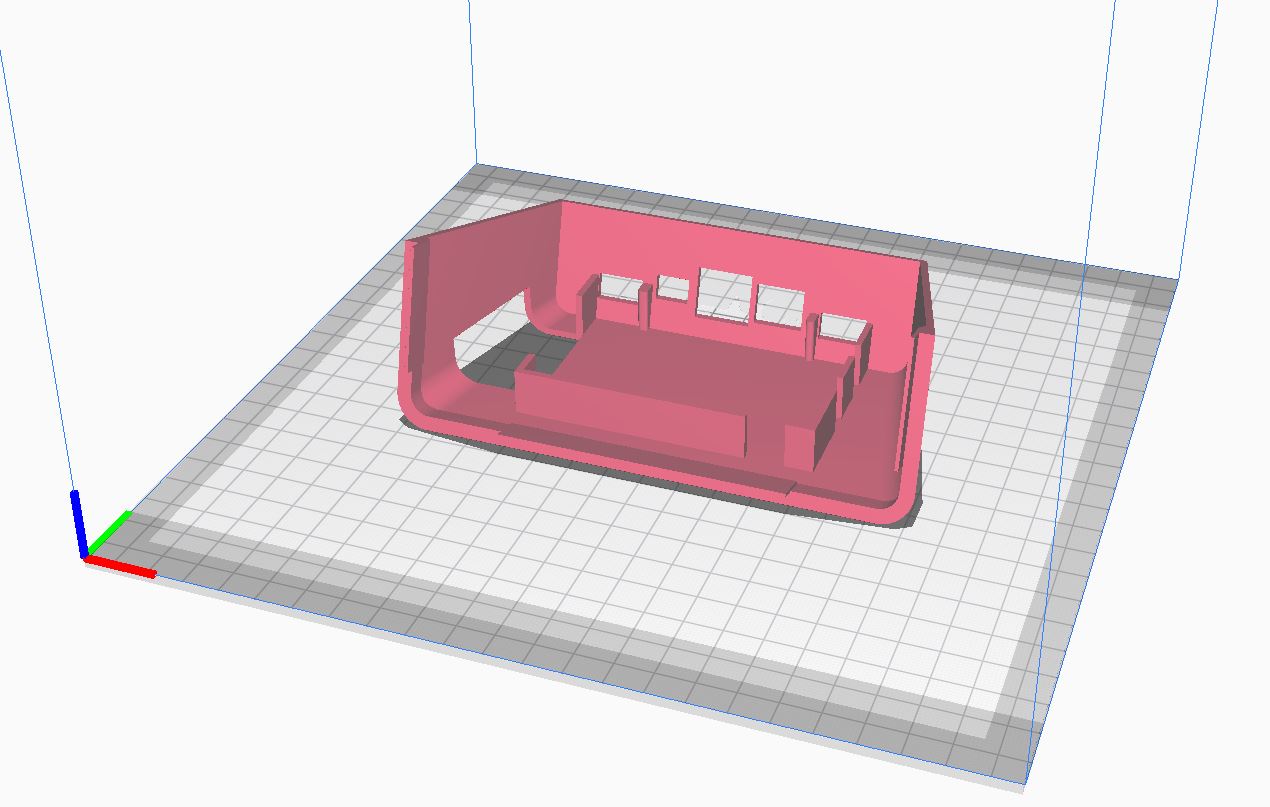

My intention here is that this shell is broken into 3 parts for best FDM printing. Even with these breaks there will need to be some supports. You will need to work out what works best for your printer. The design is intended that the three parts are super glued together on the face of each tab. The VIM3(L) board will need to be hot glued with some small dots to the internal supports. Once an M2X board and a heatsink is on the VIM, you lose the holes for mounting anyway. It wouldn’t need to be extensive. I also expect that the cut outs in the rear for the ports might need to be sanded / coaxed to fit perfectly. I made them slightly oversized and you might get lucky.

I did not put in a recess for the touchscreen, as in my experience, the recess would be so shallow the print supports in this area are annoying to clean up.

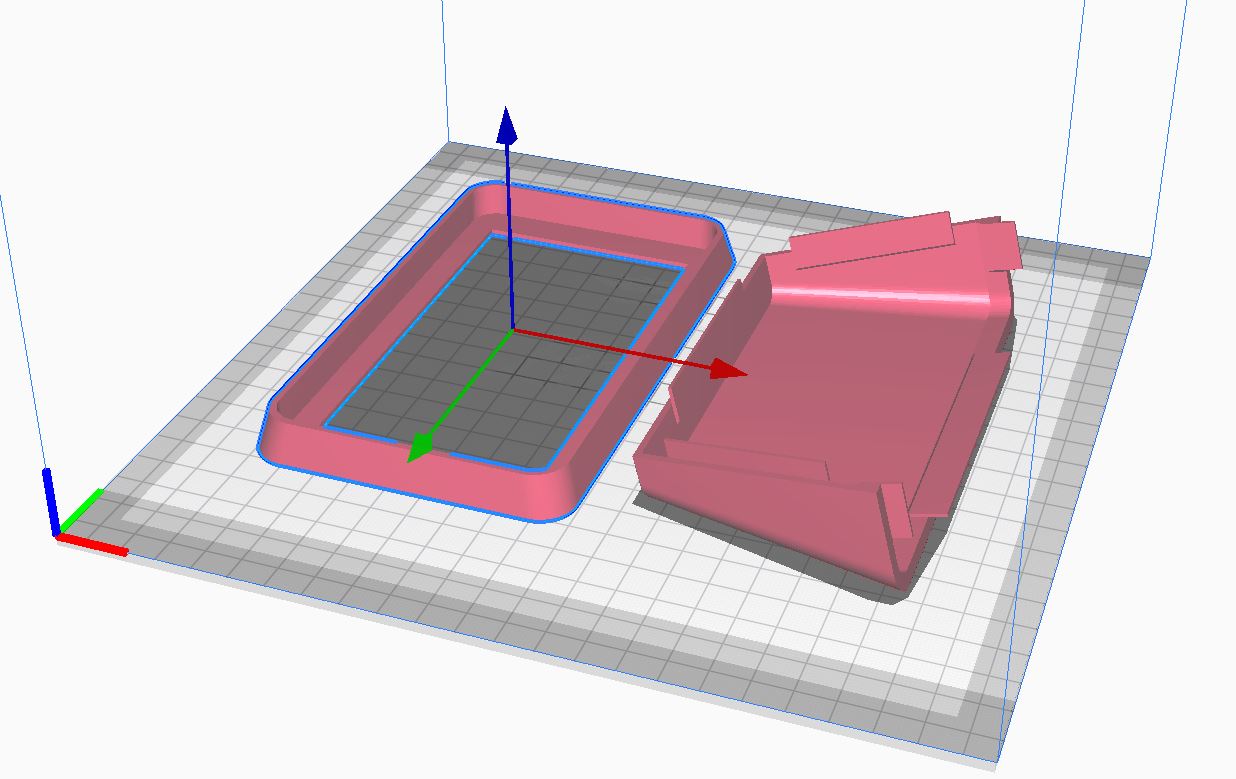

The intention of the design is to print with the face down on the printer, the top side down and the bottom side down. Again, you might have to play with this.

I did not put any ventilation holes on the bottom, but I lifted the board a good height above the bottom surface to allow more airflow. This with the cut out for the buttons should allow enough air flow, but again - tune as you see fit.

Clock Case v1 - Front

Clock Case v1 - Bottom

Clock Case v1 - Top